The future of Supplier Relationship Management systems: Navigating new trends and innovations

Excited to unveil insights on the future of Supplier Relationship Management systems! From AI-driven analytics to blockchain transparency, discover how innovation is reshaping supplier interactions. Don't miss out!

In today's interconnected global marketplace, managing supplier relationships has become increasingly complex. The addition of Supplier Relationship Management (SRM) systems has revolutionized how businesses interact with their suppliers, streamlining processes, optimizing efficiency and fostering collaboration.

However, as technology continues to evolve at a rapid pace, the future of SRM systems holds exciting prospects and transformative innovations that promise to redefine the landscape of supplier management. In this article, we delve into the emerging trends and innovations shaping the future of SRM systems, exploring their implications for businesses and the broader supply chain ecosystem.

One of the most significant advancements in SRM systems is the integration of artificial intelligence (AI) and predictive analytics. Traditional SRM systems rely on historical data to assess supplier performance and make informed decisions. However, AI-powered SRM systems go a step further by analyzing vast amounts of data from various sources, including historical supplier performance, market trends and even external factors like geopolitical events or natural disasters. By leveraging machine learning algorithms, these systems can forecast supplier behavior, identify potential risks and optimize decision-making processes in real time.

The adoption of AI-powered predictive analytics enables businesses to adopt a proactive approach to supplier management. Rather than reacting to issues as they arise, organizations can anticipate disruptions, mitigate risks and capitalize on opportunities before they impact operations. For example, AI algorithms can analyze supplier performance metrics to identify early warning signs of potential quality issues or delivery delays. By alerting stakeholders to these risks, businesses can take preemptive action to address them, thereby minimizing disruptions to production schedules and customer satisfaction levels.

Moreover, AI-powered SRM systems can optimize various aspects of supplier management, including supplier selection, contract negotiations and performance monitoring. By analyzing historical data and identifying patterns and trends, these systems can recommend the most suitable suppliers for specific requirements, negotiate favorable terms & conditions and monitor supplier performance against predefined KPIs. This data-driven approach enables businesses to make more informed decisions, optimize supplier relationships and drive continuous improvement across the supply chain ecosystem.

Blockchain Technology for Transparency and Traceability

Blockchain technology has emerged as a game-changer in supply chain management, offering unparalleled transparency, traceability and security. By creating a decentralized ledger of transactions, blockchain technology enables all parties involved in a supply chain to record and verify the authenticity and integrity of data in real time. This transparency not only enhances trust and accountability but also reduces the risk of fraud, counterfeiting and other malicious activities.

In the context of SRM systems, blockchain technology holds immense promise for enhancing transparency and traceability across the entire supplier lifecycle. From supplier onboarding and qualification to contract management and payment processing, blockchain-powered SRM systems can create immutable records of transactions and interactions, providing a single source of truth for all parties involved. This enhanced visibility enables businesses to track the origin, provenance and authenticity of products and raw materials, ensuring compliance with regulatory requirements and ethical sourcing standards.

Supplier Collaboration Platforms

In the future, SRM systems will evolve into comprehensive collaboration platforms that facilitate seamless communication and collaboration between buyers and suppliers. These platforms will integrate a wide range of features and functionalities, including instant messaging, document sharing, collaborative planning and performance tracking, enabling real-time collaboration across geographies and time zones.

By breaking down silos and fostering closer relationships between buyers and suppliers, collaboration platforms enhance efficiency, reduce lead times and drive innovation throughout the supply chain ecosystem. For example, suppliers can collaborate with buyers on product design and development, sharing ideas, feedback and insights to create innovative solutions that meet customer needs. Similarly, buyers can work closely with suppliers to optimize production schedules, minimize inventory levels and reduce supply chain costs.

Additionally, collaboration platforms enable businesses to build trust and transparency with their suppliers, fostering long-term partnerships based on mutual respect and shared goals. By providing a centralized platform for communication and collaboration, these systems streamline interactions between buyers and suppliers, reducing the need for emails, phone calls and face-to-face meetings. This not only saves time and resources but also enhances visibility into supplier performance, enabling businesses to identify areas for improvement and drive continuous innovation across the supply chain.

Robotic Process Automation (RPA)

Robotic Process Automation (RPA) is poised to revolutionize supplier management by automating repetitive, rule-based tasks such as invoice processing, order management, and supplier onboarding. By deploying software robots to handle these mundane tasks, businesses can free up human resources to focus on value-added activities such as strategic supplier negotiations, relationship building and innovation.

RPA-powered SRM systems leverage artificial intelligence and machine learning algorithms to mimic human actions and automate routine tasks with a high degree of accuracy and efficiency. For example, software robots can extract data from invoices, match purchase orders with delivery receipts and process payments without human intervention. Similarly, they can onboard new suppliers, verify their credentials and update relevant information in the SRM system, all while ensuring compliance with regulatory requirements and internal policies.

By automating manual processes and reducing the need for human intervention, RPA-powered SRM systems not only enhance operational efficiency but also improve accuracy, reduce errors and accelerate decision-making processes. By standardizing and automating workflows, these systems enable businesses to enforce consistency and compliance across the supplier lifecycle, minimizing the risk of errors, discrepancies and non-compliance issues.

Advanced Data Analytics for Performance Optimization

In the future, SRM systems will leverage advanced data analytics techniques such as machine learning and prescriptive analytics to optimize supplier performance continuously. These analytics capabilities enable businesses to gain deeper insights into supplier behavior, identify patterns and trends and optimize various aspects of supplier management, including sourcing strategies, supplier selection, pricing negotiations and risk management.

Machine learning algorithms can analyze vast amounts of structured and unstructured data from internal and external sources, including historical supplier performance, market trends, customer feedback and social media sentiment. By identifying correlations and causations between different variables, these algorithms can generate actionable insights and recommendations to help businesses make more informed decisions.

Prescriptive analytics takes this a step further by not only predicting future outcomes but also recommending specific actions to achieve desired outcomes. For example, prescriptive analytics can recommend the most cost-effective sourcing strategies based on current market conditions, supplier capabilities and business objectives. Similarly, they can identify potential risks and vulnerabilities in the supply chain and recommend proactive measures to mitigate them, such as diversifying the supplier base or implementing contingency plans.

By harnessing the power of data, businesses can drive continuous improvement, foster innovation, and maintain a competitive edge in the marketplace. Moreover, by integrating advanced data analytics capabilities into SRM systems, businesses can optimize supplier relationships, reduce costs and mitigate risks, thereby enhancing supply chain resilience and agility.

Integration with Internet of Things (IoT) Devices

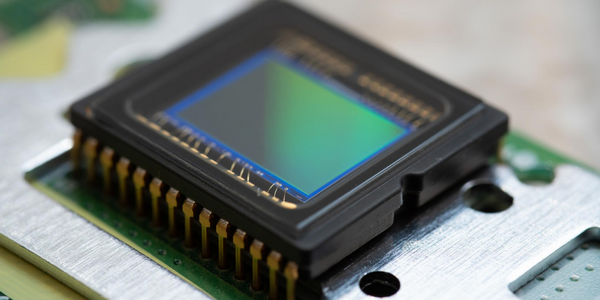

The Internet of Things (IoT) is transforming supply chain management by enabling real-time monitoring and tracking of goods throughout the supply chain. In the future, SRM systems will integrate seamlessly with IoT devices such as RFID tags, sensors, and smart devices, allowing businesses to monitor inventory levels, track shipments and assess supplier performance in real time.

For example, RFID tags and sensors can be attached to products and shipments to track their location, condition, and status as they move through the supply chain. By collecting and analyzing data from these IoT devices, SRM systems can provide real-time visibility into the status and whereabouts of goods, enabling businesses to optimize inventory management, reduce stockouts and improve order fulfillment rates.

IoT devices can be used to monitor supplier performance metrics such as lead times, delivery reliability, and product quality. For example, sensors installed on manufacturing equipment can track production rates and detect potential issues or malfunctions in real time. Similarly, IoT-enabled devices can monitor environmental conditions such as temperature, humidity and vibration during transportation and storage, ensuring that products arrive in optimal condition.

By leveraging IoT technology, businesses can gain deeper insights into supplier performance, optimize supply chain processes and enhance customer satisfaction levels. Moreover, by integrating IoT data into SRM systems, businesses can improve decision-making processes, reduce risks and drive continuous improvement across the entire supply chain ecosystem.

Focus on Sustainability and Ethical Sourcing

With increasing consumer awareness and regulatory scrutiny, sustainability and ethical sourcing have become critical considerations for businesses. In the future, SRM systems will place greater emphasis on monitoring and managing supplier sustainability practices, including environmental impact, labor conditions and ethical sourcing standards.

By integrating sustainability metrics into supplier performance evaluations, SRM systems can provide visibility into suppliers' sustainability practices and performance. For example, businesses can track suppliers' carbon emissions, energy consumption and waste generation to assess their environmental impact. Similarly, they can monitor suppliers' labor practices, including working conditions, wages and employee rights, to ensure compliance with ethical standards and regulations.

Moreover, SRM systems can facilitate collaboration on sustainability initiatives between buyers and suppliers, enabling them to work together to reduce environmental footprint, promote social responsibility, and drive positive social and environmental outcomes. For example, businesses can collaborate with suppliers to implement energy-efficient production processes, reduce waste & emissions and promote responsible sourcing practices.

By prioritizing sustainability and ethical sourcing, businesses can enhance their brand reputation, attract environmentally and socially conscious consumers and create long-term value for all stakeholders. Moreover, by integrating sustainability considerations into SRM systems, businesses can make more informed decisions, mitigate risks and drive positive change across the entire supply chain ecosystem.

Conclusion

The future of Supplier Relationship Management systems holds immense promise, driven by emerging technologies, changing market dynamics, and evolving business needs. From AI-powered predictive analytics to blockchain-enabled transparency, the next generation of SRM systems will empower businesses to optimize supplier relationships, mitigate risks, drive innovation and create sustainable value across the entire supply chain ecosystem.

By embracing these trends and innovations, businesses can navigate the complexities of the modern marketplace and position themselves for success in the years to come. Whether it's leveraging AI to predict supplier behavior, harnessing blockchain to ensure transparency and traceability, or integrating IoT devices to monitor supplier performance, the future of SRM systems is bright and full of opportunities for businesses to thrive in an increasingly competitive and dynamic environment.